Arc Flash Hazards - Understanding and Protection

Many arc flash burn injuries occur when the arc ignites flammable clothing, rather than directly from the arc itself.

What is an Arc Flash?

An electric arc is a powerful electrical discharge that generates a burst of hot gas, reaching temperatures upwards of 35,000 °F (19,400 °C). This intense heat is almost four times hotter than the surface of the sun. The energy released during an electric arc quickly heats and vaporizes the metal carrying the current, creating an explosive arc blast that produces loud noises, supersonic shockwaves, and molten metal fragments.

Choosing Correct AR PPE Makes a Difference

Flammable clothing can pose a serious risk in environments where arc flash hazards are present. It is important to wear appropriate Arc Rated PPE (AR PPE) to protect against the potential dangers of an arc flash incident. Choosing the right AR PPE can make a significant difference in preventing injuries and ensuring the safety of workers in high-risk environments. View Flame Resistant Clothing from Safety Smart Gear.

Flammable clothing can pose a serious risk in environments where arc flash hazards are present. It is important to wear appropriate Arc Rated PPE (AR PPE) to protect against the potential dangers of an arc flash incident. Choosing the right AR PPE can make a significant difference in preventing injuries and ensuring the safety of workers in high-risk environments. View Flame Resistant Clothing from Safety Smart Gear.

The following information is derived from the Arc Flash Guides presented by OSHA's Electrical Flash Hazards resources page.

Common Electrical Work Myths

MYTH #1 Your work is not energized

FACT: Most electrical work is done while the equipment is

energized, exposing workers to electrical shock and

arc flash hazards. Many workers mistakenly believe that

they do not need arc rated (AR) personal protective

equipment (PPE) because they don’t perform energized

work.

Electrical equipment and circuits are either energized OR they are locked-out/tagged-out for maintenance. “Deenergizing” is not the same as lockout/tagout, and most tasks where lockout/tagout has not been applied to equipment would be considered energized work.1

It is crucial to understand that deenergizing without locking/tagging out does not eliminate the electrical shock and arc flash hazards.

MYTH #2 My work is justified, so it's electrically safe

FACT: Justified energized work refers to specific situations where working on or near energized electrical equipment is deemed necessary and “justified” under certain conditions.

It may not be feasible or practical to deenergize equipment for maintenance or other tasks (such as interrupting power to a hospital).

Even when work is considered “justified,” strict safety measures must be implemented and followed to minimize the risks associated with electrical hazards.

Establishing Boundaries Around Arc Flash Hazards

Arc flash incidents pose significant risks to worker safety. However there are three types of boundaries to consider when approaching energized electrical equipment. It is important to know all approach boundaries and who may cross them and remain safe.

What are Approach Boundaries?

NFPA 70E recommends that the closer a worker gets to an

electrical hazard the more training and protection they should

have.

NFPA 70E recommends that the closer a worker gets to an

electrical hazard the more training and protection they should

have.

These specific approach boundaries can vary depending on factors such as the voltage level of the equipment1 and the type of work being performed. Other factors to consider when determining the approach boundary is the electrical equipment configuration and working condition, such as enclosure type or the presence of insulating barriers.

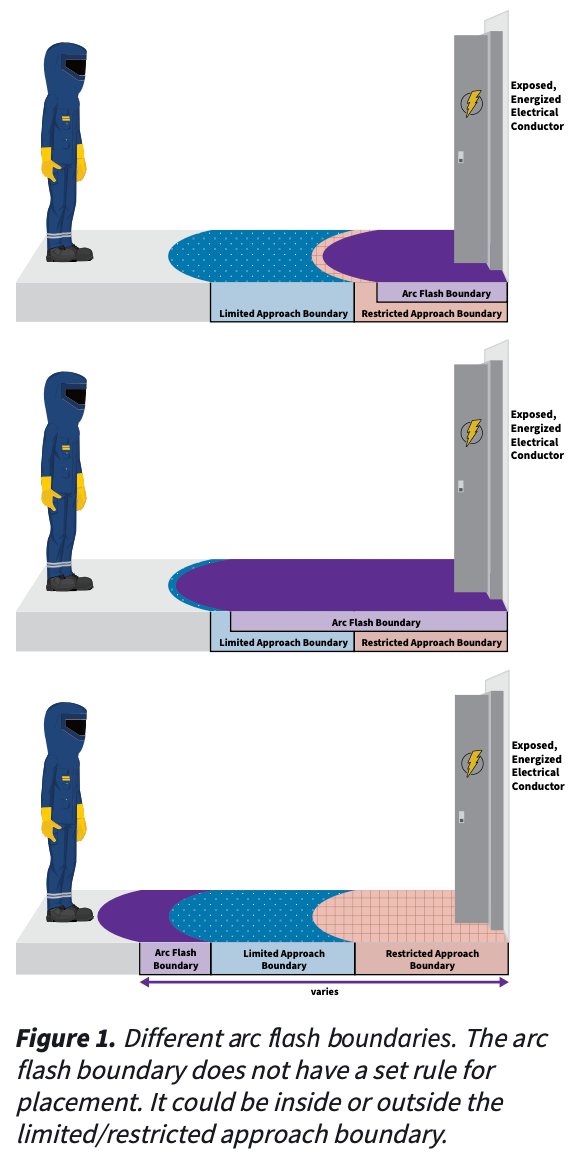

There are three types of approach boundaries. Two of them, the restricted approach boundary and the limited approach boundary, protect against electric shock. The third, the arc flash boundary, protects against exposure to arc flash.

Higher voltages may result in larger approach boundaries

- Restricted approach boundary: Inside this boundary is the highest likelihood of electric shock. Under no

circumstance should an unqualified worker ever be permitted to cross the restricted boundary. Qualified workers2

should never enter or take conductive objects within the restricted approach boundary unless they are using

appropriate PPE, and the conductive object is insulated.

- Limited approach boundary: Inside this boundary an electric shock hazard exists. Wherever it is necessary for

an unqualified worker to cross the limited approach boundary, the worker should be supervised and

accompanied by a qualified worker while inside the limited approach boundary. However, if the arc flash

boundary is within or outside the limited approach boundary, the rules for the arc flash boundary have priority.

- Arc flash boundary: At this boundary a worker without appropriate PPE could receive second degree burns from an arc flash. 3 Similar to the restricted boundary, under no circumstance should an unqualified worker ever be permitted to cross the arc flash boundary.

The arc flash boundary does not have a direct relationship with the electric shock approach boundaries (see Figure 1). While the restricted approach boundary is always within the limited approach boundary, the arc flash boundary can be either inside (see top and middle of Figure 1) or outside (see bottom of Figure 1) of these boundaries. Whenever there is a likelihood of arc flash incident, use both the arc flash boundary and the limited/restricted approach boundaries to ensure worker safety.

Being Aware of Arc Flash Hazards

Anyone who works around energized electrical equipment is at risk of arc flash hazards. It is important to identify, assess, and control these hazards to maintain a safe work environment.

There are several conditions that contribute to arc flashes. Faulty, damaged, dirty, or improperly maintained electrical equipment increases the risk for an arc flash incident to occur while the magnitude of the electrical energy/voltage increases its severity. Any inadvertent movement within the restricted or arc flash boundaries, especially when conductive tools are used, also increases the likelihood of an arc flash incident.

Prevention Methods

Methods to prevent arc flashed include:

- Using of lockout/tagout procedures, in compliance with 29 CFR 1910.147, and ensuring the deenergization of electrical equipment is the strongest mitigation measure against all electrical hazards as it eliminates and removes the hazard entirely.

- Identifying and using approach boundaries for qualified and unqualified employees (For more information on Approach Boundaries, see: Establishing Boundaries Around Arc Flash Hazards).

- Maintaining electrical equipment as required by 29 CFR 1910.334, reduces the risk of an arc flash incident from occurring.

- Applying safe work practices to deenergize and test for the absence of voltage and the use of personal protective grounds in compliance with 29 CFR 1910.333. Notably, arc flashes can occur at voltages below 240V.

- Conducting an arc flash risk assessment to assess the potential for an arc flash hazard, determine the available incident energy of the exposed energized electrical conductor or part, and help in determining and selecting appropriate arc-rated PPE.

- Using and maintaining arc-rated PPE, and insulated tools in compliance with 29 CFR 1910.137 and 29 CFR 1910.335.

- Training workers, in compliance with 29 CFR 1910.332, to ensure they are aware of the hazards they are likely to face and the means to mitigate their risks.

Workers’ Rights

Workers have the right to:

- Working conditions that do not pose a risk of serious harm.

- Receive information and training (in a language and vocabulary the worker understands) about workplace hazards, methods to prevent them, and the OSHA standards that apply to their workplace.

- Review records of work-related injuries and illnesses.

- File a complaint asking OSHA to inspect their workplace if they believe there is a serious hazard or that their employer is not following OSHA’s rules. OSHA will keep all identities confidential.

- Exercise their rights under the law without retaliation, including reporting an injury or raising health and safety concerns with their employer or OSHA. If a worker has been retaliated against for using their rights, they must file a complaint with OSHA as soon as possible, but no later than 30 days. For additional information, see OSHA’s Workers Rights and Protections page.

Additional Resources

OSHA has produced the following guides to assist employers and employees in understanding and protecting against arc flash hazards:

Arc Flash Guides For Employees

Establishing Boundaries Around Arc Flash Hazards

Being Aware of Arc Flash Hazards

Arc Flash Guide For Employers

Protecting Employees from Electrical Arc Flash Hazards

Contact Safety Smart Gear for help with understanding or ordering Arc Flash Protective Flame Resistant Clothing for you or with bulk discounts for your team. Call (508) 248-3141

Recent Posts

-

Choosing Hand Protection: A Guide to Safety Work Gloves

Why Hand Protection Matters Our hands are constantly on the front lines at work gripping tools, hand …Nov 20th 2025 -

Balaclavas - Many Styles Fit The Job

Balaclavas - Many Styles Fit The Job When it comes to protection and comfort on the job, few accesso …Oct 24th 2025 -

Understanding Mips Science

Comprehending the Science within Mips Conceived by an engineer and a neuroscientist, the Mips® brai …Sep 22nd 2025